Steps to Balance a Pressure Pot

(Click here to download as a PDF)

- Set the fluid regulator to 10psi

- Shut off the atomization air to the spray gun

- Pull trigger on spray gun and flow liquid into a measuring cup for 15 seconds. Multiply fluid ounces in the measuring cup by 4 to determine fluid ounces per minute.

- Fluid ounces per minute should be between 10-12oz which is equal to 2.5-3oz in 15 seconds (universal paint company recommendations)

- Raise or lower fluid pressure to achieve desired fluid flow. When lowering pressure make sure to relieve pressure on pot before retesting

- Set the air regulator to deliver 30-45psi of air pressure for conventional/high efficiency spray guns or to deliver max psi for HVLP spray guns

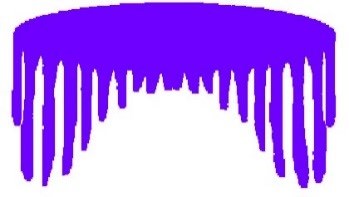

- Spray a horizontal test pattern and balance the spray pattern

Balanced spray pattern

Balanced spray pattern

Air pressure too low or fluid flow too high

Air pressure too low or fluid flow too high

Air pressure too high or fluid flow too low

Air pressure too high or fluid flow too low

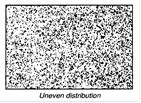

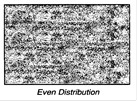

8. Spray a fast pass to determine particle size

9. Adjust air and fluid to even out distribution when spraying a pass

Final Adjustment

1. Spray a part, piece or vehicle to see if:

a. Proper finish quality can be met

b. Production can be maintained

c. The settings match the painter’s spray tempo